• Back to Marketing Options Articles List •

From Virtual to Reality:

Reshaping the Way We Build Foundries

Brian Judd

Design Engineer

Marketing Options, LLC

Simple Solutions That Work!

Fall 2021

ARTICLE TAKEAWAYS:

AR/VR: THEN AND NOW

The advent of new technology can revolutionize an industry. Computer Aided Design (CAD) has already revolutionized engineering and design, and the effects of 3D printing are rippling through the manufacturing world. Now Augmented Reality (AR) and Virtual Reality (VR) technologies are emerging as the next major changeagent in many sectors. Industry analysts are predicting that the AR/ VR market will be huge; $8.8 billion since 2012, with $2.2 billion in 2016 alone. It's expected that by 2020, AR and VR combined will be a $120 billion industry.

Heads-Up Displays (HUDs), forerunners of modern augmented reality systems, were developed for use in military aircraft as early as 1942. Since the introduction of smartphones, basic forms of AR have become widely available in the form of apps like Google Translate, Layar or Yelp’'s Monocle feature.

New applications for AR and VR are emerging almost daily. The US Navy is using AR to enhance the safety and mission effectiveness of deep sea diving operations. The US Air Force has gone even further; the F-35 uses an AR system instead of a conventional HUD. Jurors are now able to virtually experience crime scenes and doctors can use VR to guide remotely controlled robotic surgeons.

THE SPECTRUM: FROM FLAT SCREENS TO AUGMENTED REALITY TO IMMERSIVE VR

The essential concept behind ‘mixed reality' is displaying computer generated virtual content combined with or seamlessly replacing reality. Powerful extensions to this core concept allow users to interact with the virtual, to share a virtual space with other users, and/or to move around in a virtual space freely.

The simplest implementation of AR, widely available currently, is to display virtual content overlaid on a camera feed from a smartphone or tablet. Flat-screen AR is low-cost, but also low-immersion. It allows a limited field of view into the virtual world, and the restricted computing capabilities of mobile devices limit detail and fidelity. This type of AR is useful as a visualization aid or training tool.

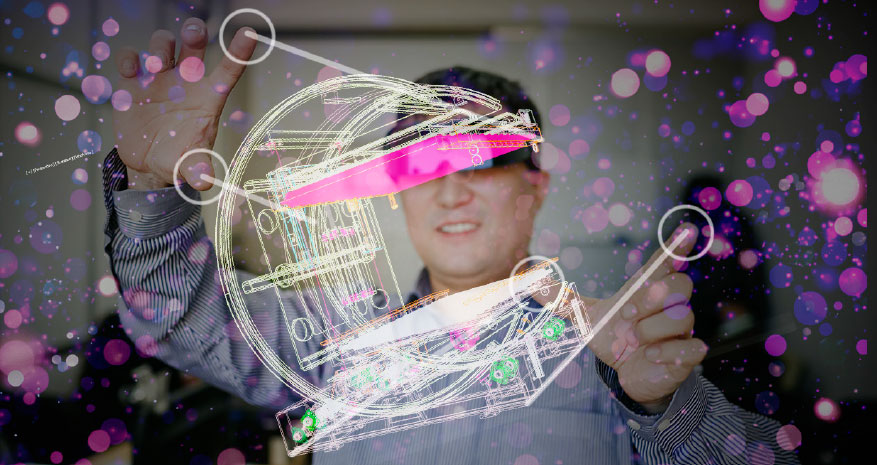

An intermediate level of mixed reality is the AR head-mounted display (HMD), with motion and hand tracking. This type of system consists of a helmet or goggle-like device with clear lenses or a visor, on which can be displayed virtual content. Users can also share a virtual space with each other, facilitating 'virtual conferencing' and collaboration. This level of AR is still in the early phases, but companies like Microsoft ®, MagicLeap ®, and Meta ® are developing products that will allow full implementation of HMD-based AR.

At the top of the spectrum is the fully immersive VR headset connected to a powerful computer system or workstation. This is a goggle-like display that completely covers users' field of view with virtual imagery, and optionally includes audio. Some systems allow 'room-scale' VR, which allows users to move freely within a delineated real space as they explore their virtual environment. These systems have the same basic capabilities as HMD AR, but they replace perception of reality rather than combine with it.

MOVING FROM VIRTUAL TO REAL

Foundries are one of the many industries set to derive benefits from the mixed reality revolution.

Foundry Layout and Design

A foundry or factory layout can be rapidly assembled and modified during a collaborative session and displayed on-screen for multiple participants, either local or networked. Users can choose and position machinery or components inside a virtual copy of the foundry environment. Hand tracking allows users to 'grab' virtual objects and position them directly, regardless of whether they are in the room or connected via network. Once a layout has been assembled, users can tour and experience the design. Immersive VR will be especially valuable to system integrators, allowing investigation of production flow and human factors very early in the planning stages. This type of experience will translate well to all personnel and communicate a design even more effectively than flat drawings.

Equipment and Systems Training

In most instances, the more closely training adheres to reality, the more effective it has proven. It is now possible to combine virtual training aids with reality to enhance effectiveness even further. Flatscreen and HMD AR allow text or highlights to be overlaid directly on a piece of equipment, helping to eliminate confusion or delay. Automotive manufacturers are beginning to implement AR owner's manuals that highlight, over video from a tablet, components under the hood and show the user how to perform maintenance and repair tasks. The same concept can apply to training for nearly any kind of complex machinery or process.

VR users be able to not only interact with virtual copies of machinery in order to learn proper operation, they will be able to actually get a feel for the conditions involved in the task. The combination of high visual fidelity and hand tracking accuracy means that users can develop muscle-memory for the operation of equipment that they have never even touched in reality.

Safety Training

Accurate understanding of safety procedures is a top priority across industries. Not only can AR/VR assist in learning proper operating procedures, it can also be used to present unusual or emergency situations more cheaply and effectively. Drills can only go so far in emulating the experience involved in an emergency, and can be expensive and time consuming to conduct. Mixed reality training exercises can present users with a full auditory and visual representation of the circumstances, which is especially valuable when those senses might be obscured during a real event due to environmental hazards.

Job Aids

Applications can also be developed that combine image-recognition software with the display to prompt users based on the exact circumstances they are faced with. Such a system would be able to help users find a specific part in a tray of mixed parts, or display the proper steps to handle an unusual operating condition. Operations manuals and other references can also be displayed via AR, enabling operators to continue work while accessing helpful information related to the task at hand.

Sales and Marketing

Any piece of equipment can be virtually setup in even a small physical space, allowing multiple users to view and interact with the machinery. Demonstrations can be conducted simultaneously for users in different locations, saving time and travel expenses.

Digital files for a whole line of equipment can fit on one computer or thumb-drive, allowing an entire virtual catalog to be easily taken to meetings or tradeshows. While one piece of equipment may be physically on display at a tradeshow booth, attendees could experience a full product line or even complete foundry layouts right at the show. The user's view can also be show on a large flat-screen as a way to share the experience with other tradeshow attendees and to create interest.

These are early days for AR and VR technology, but the potential is already proving to be limitless. AR and VR are poised to create sweeping improvements to design, integration, training and even marketing in the industrial and manufacturing arena.