Equipment and Systems Training

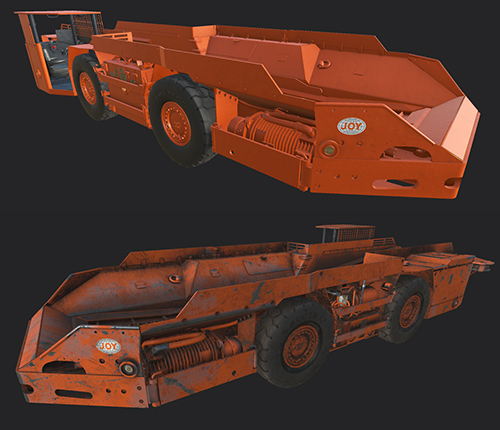

In most instances, the more closely training adheres to reality, the more effective it has proven. It is now possible to combine virtual training aids with reality to enhance effectiveness even further. Flat-screen and HMD AR allow text or highlights to be overlaid directly on a piece of equipment, helping to eliminate confusion or delay. Automotive manufacturers are beginning to implement AR owner’s manuals that highlight, over video from a tablet, components under the hood and show the user how to perform maintenance and repair tasks. The same concept can apply to training for nearly any kind of complex machinery or process.

VR users be able to not only interact with virtual copies of machinery in order to learn proper operation, they will be able to actually get a feel for the conditions involved in the task. The combination of high visual fidelity and hand tracking accuracy means that users can develop muscle-memory for the operation of equipment that they have never even touched in reality.

Safety Training

Accurate understanding of safety procedures is a top priority across industries. Not only can AR/VR assist in learning proper operating procedures, it can also be used to present unusual or emergency situations more cheaply and effectively. Drills can only go so far in emulating the experience involved in an emergency, and can be expensive and time consuming to conduct. Mixed reality training exercises can present users with a full auditory and visual representation of the circumstances, which is especially valuable when those senses might be obscured during a real event due to environmental hazards.

Job Aids

Applications can also be developed that combine image-recognition software with the display to prompt users based on the exact circumstances they are faced with. Such a system would be able to help users find a specific part in a tray of mixed parts, or display the proper steps to handle an unusual operating condition. Operations manuals and other references can also be displayed via AR, enabling operators to continue work while accessing helpful information related to the task at hand.

Sales and Marketing

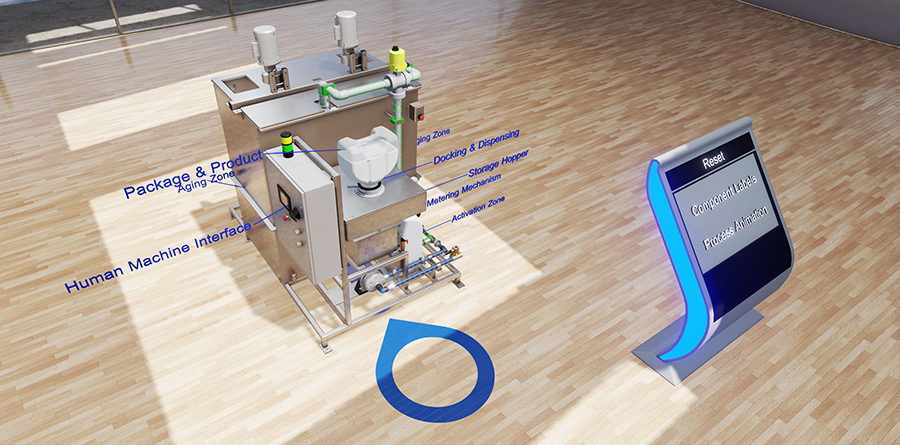

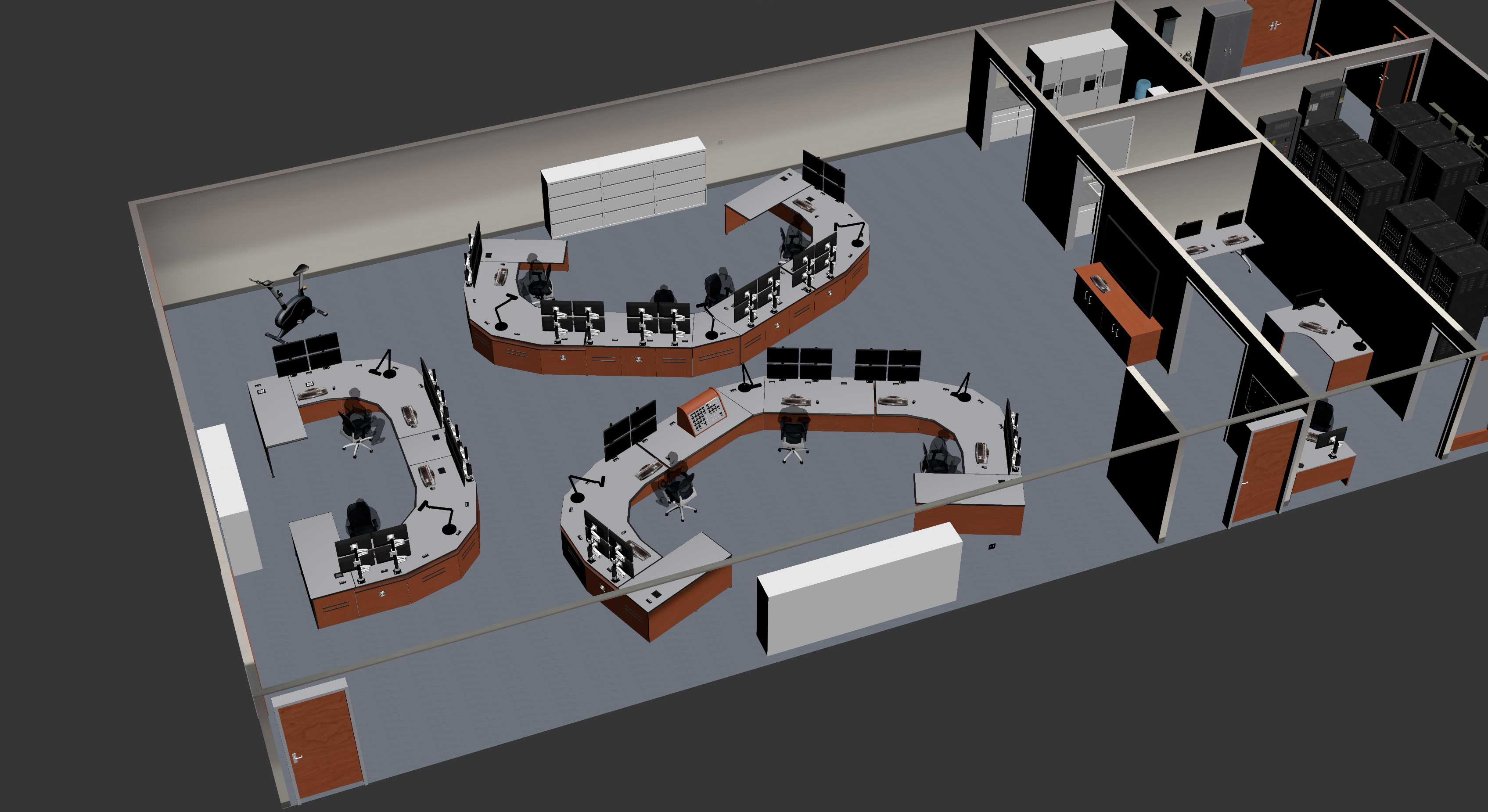

Any piece of equipment can be virtually setup in even a small physical space, allowing multiple users to view and interact with the machinery. Demonstrations can be conducted simultaneously for users in different locations, saving time and travel expenses.

Digital files for a whole line of equipment can fit on one computer or thumb-drive, allowing an entire virtual catalog to be easily taken to meetings or tradeshows. While one piece of equipment may be physically on display at a tradeshow booth, attendees could experience a full product line or even complete foundry layouts right at the show. The user’s view can also be shown on a large flat-screen as a way to share the experience with other tradeshow attendees and to create interest.

These are early days for AR and VR technology, but the potential is already proving to be limitless. AR and VR are poised to create sweeping improvements to design, integration, training and even marketing in the industrial and manufacturing arena.

REQUEST A VIRTUAL REALITY DEMO